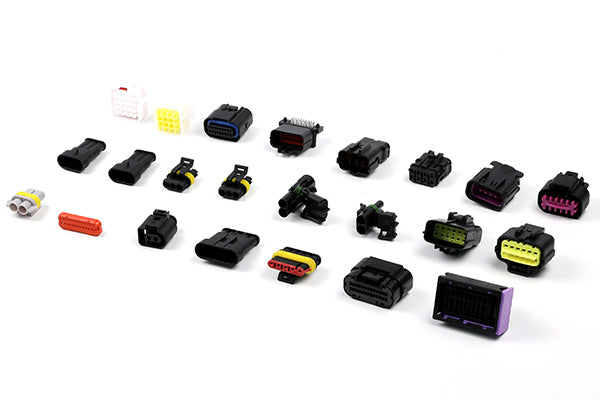

Automotive connector

Automotive connector

Automotive Electrical Connectors: A Brief Introduction

An automotive electrical connector is a electro-mechanical device used to join electrical circuits together, providing a secure and reliable interface within a vehicle's wiring harness. They are fundamental components in modern vehicles, enabling the transmission of power, signals, and data between countless electronic systems.

Key Functions and Importance:

-

Modular Assembly: Connectors allow different components (e.g., ECUs, sensors, actuators, infotainment systems) to be manufactured separately and connected easily during vehicle assembly, streamlining the production process.

-

Serviceability: They facilitate easy installation, maintenance, and replacement of components without requiring complex rewiring.

-

Environmental Protection: Designed to withstand the harsh conditions of an automotive environment, including vibration, temperature extremes, moisture, dust, and exposure to chemicals.

-

Electrical Integrity: They ensure stable and low-resistance electrical connections, preventing short circuits, voltage drops, and signal interference.

Critical Design Features:

-

Housing: Typically made from durable, high-temperature plastic (e.g., PBT, PPS, Nylon). It physically holds the terminals and provides key features like locking mechanisms, polarization (to prevent mis-mating), and environmental seals.

-

Terminals (Contacts): The metal pins and sockets that make the actual electrical connection. They are usually made from copper alloys (e.g., brass, phosphor bronze) and plated with tin, silver, or gold to enhance conductivity and prevent corrosion.

-

Sealing System: Crucial for "weather-pack" connectors. Uses rubber grommets, seals, and plugs to create an IP (Ingress Protection) rated barrier against moisture and contaminants.

-

Locking Mechanism: Essential to prevent connectors from vibrating loose. Common types include lever locks, latch locks, and push-pull locks.

-

CPA (Connector Position Assurance): A secondary locking device that provides an audible and tactile click to confirm the primary lock is fully engaged.

-

TPA (Terminal Position Assurance): A secondary lock inside the housing that ensures the metal terminals are fully seated and locked into place, preventing them from backing out.

Common Types and Applications:

-

Wire-to-Wire: Connect two wire harnesses together.

-

Wire-to-Board: Connect a wire harness to a printed circuit board (PCB), common in control modules.

-

Board-to-Board: Connect two PCBs together.

-

High-Voltage Connectors: Specifically designed for hybrid and electric vehicles (EVs) to handle high voltage and current from the battery to the inverter and motor. They are often orange and feature complex safety interlock systems.

-

RF Connectors: For coaxial cables used in GPS, cellular, and radio antennas.

-

Data Bus Connectors: For high-speed data networks like CAN (Controller Area Network), LIN (Local Interconnect Network), FlexRay, and Automotive Ethernet.

Industry Standards:

Major automotive manufacturers and suppliers often adhere to standards set by international organizations like the USCAR (United States Council for Automotive Research), which defines performance and testing criteria for connectors to ensure interoperability and reliability.

無法載入取貨服務供應情況

有庫存

查看完整資訊