Heavy Duty connector

Heavy Duty connector

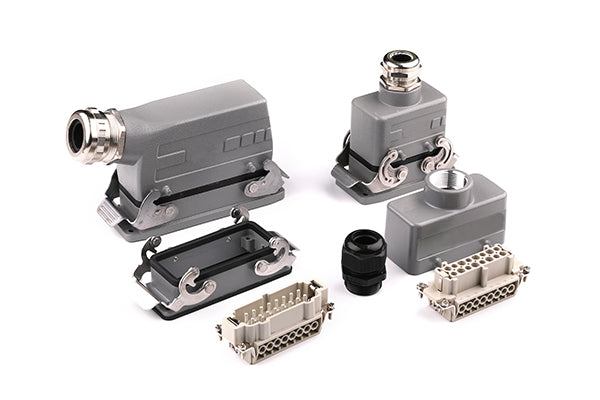

Heavy-Duty Connector (HDC): A Brief Introduction

A Heavy-Duty Connector (HDC), also often known as an Industrial Connector or by brand names like Harting Han®, Amphenol EPIC®, or Phoenix Contact COMBICON®, is a modular connector system designed specifically to provide a robust, reliable, and highly protected connection in the most demanding industrial and commercial environments. They are the workhorses of industrial automation, built to outperform standard connectors.

Core Philosophy and Key Advantages:

The primary design goal of an HDC is to simplify wiring, enhance reliability, and reduce downtime in harsh applications. They replace complex, time-consuming, and less reliable wiring methods like individual glanded cables or junction boxes.

-

Extreme Robustness: Built to withstand mechanical stress, including intense vibration, shock, and frequent mating cycles, far better than standard connectors.

-

Superior Environmental Protection: Offer very high Ingress Protection (IP) ratings, typically IP65, IP66, IP67, and even IP69K (for high-pressure, high-temperature wash-downs). They are sealed against dust, moisture, and jets of water.

-

Modularity and Flexibility: Their key feature is a modular design. Users can configure a single connector housing with a custom mix of:

-

Power contacts (high current)

-

Signal and data contacts (e.g., Ethernet, Profibus)

-

Coaxial contacts (for RF)

-

Pneumatic or fluid couplings (Hybrid Connectors)

-

-

Ease of Installation and Maintenance: Modules can be pre-wired and tested on the bench. Entire machine modules can then be quickly connected or disconnected on the factory floor, drastically reducing installation time and machine downtime for maintenance.

-

Safety: Many designs feature advanced locking mechanisms (e.g., bayonet, screw-lock) that prevent accidental disconnection and often include a protective shutter to prevent contact with live pins when unmated.

Key Components of an HDC System:

An HDC system is comprised of several integrated parts:

-

Housing (Shell): The robust outer shell, typically made of die-cast zinc alloy or high-strength engineering plastics. It provides the mechanical structure and environmental seal.

-

Hood (Plug Housing): Contains the male contacts and is attached to the cable.

-

Header (Receptacle Housing): Contains the female contacts and is mounted onto the machine or control cabinet.

-

-

Insert Modules: The heart of the modular system. These are plastic blocks that hold the actual electrical contacts. Different modules are used for power, signal, or data. They snap into the housing.

-

Contacts (Terminals): The pins and sockets within the insert modules. They are designed for high current-carrying capacity and reliable mating, often using a gas-tight crimp connection.

-

Locking Mechanism: A secure coupling system, most commonly a robust bayonet-style lock that ensures a vibration-proof connection and provides tactile and audible feedback when fully mated.

-

Sealing System: Multiple sealing points, including between the housing halves, at the cable gland entry, and between different modules, ensure the high IP rating.

Common Industry Standards:

While many HDCs are proprietary, their dimensions and performance often conform to international standards to ensure interoperability between manufacturers. The most common standard is:

-

IEC 61076-2: Specifies the dimensions and requirements for circular connectors with inner push-pull locking, which covers many HDC form factors.

Typical Applications:

Heavy-Duty Connectors are essential anywhere equipment faces harsh conditions:

-

Industrial Automation & Robotics: Connecting robotic arms, CNC machines, sensors, and motor drives.

-

Factory Floor Machinery: Presses, conveyors, and packaging equipment.

-

Process Control & Instrumentation

-

Rail Transportation: For onboard and trackside equipment.

-

Renewable Energy: In wind turbines and solar inverter systems.

-

Outdoor Infrastructure: Lighting, HVAC systems, and construction equipment.

無法載入取貨服務供應情況

有庫存

查看完整資訊